CPCB and SPCB

Central Pollution Control Board directed the State Pollution Control Boards and Pollution Control Committees for monitoring of the Air polluting gasses of the 17 categories of highly polluting industries ( pesticides, zinc, copper, aluminium, petrochemicals, the pharmaceutical industry, sugar, tanneries, power plants, iron and steel, cement, oil refineries, fertilizer, chloral alkali plants, dye and dye intermediate units, and pulp and paper)

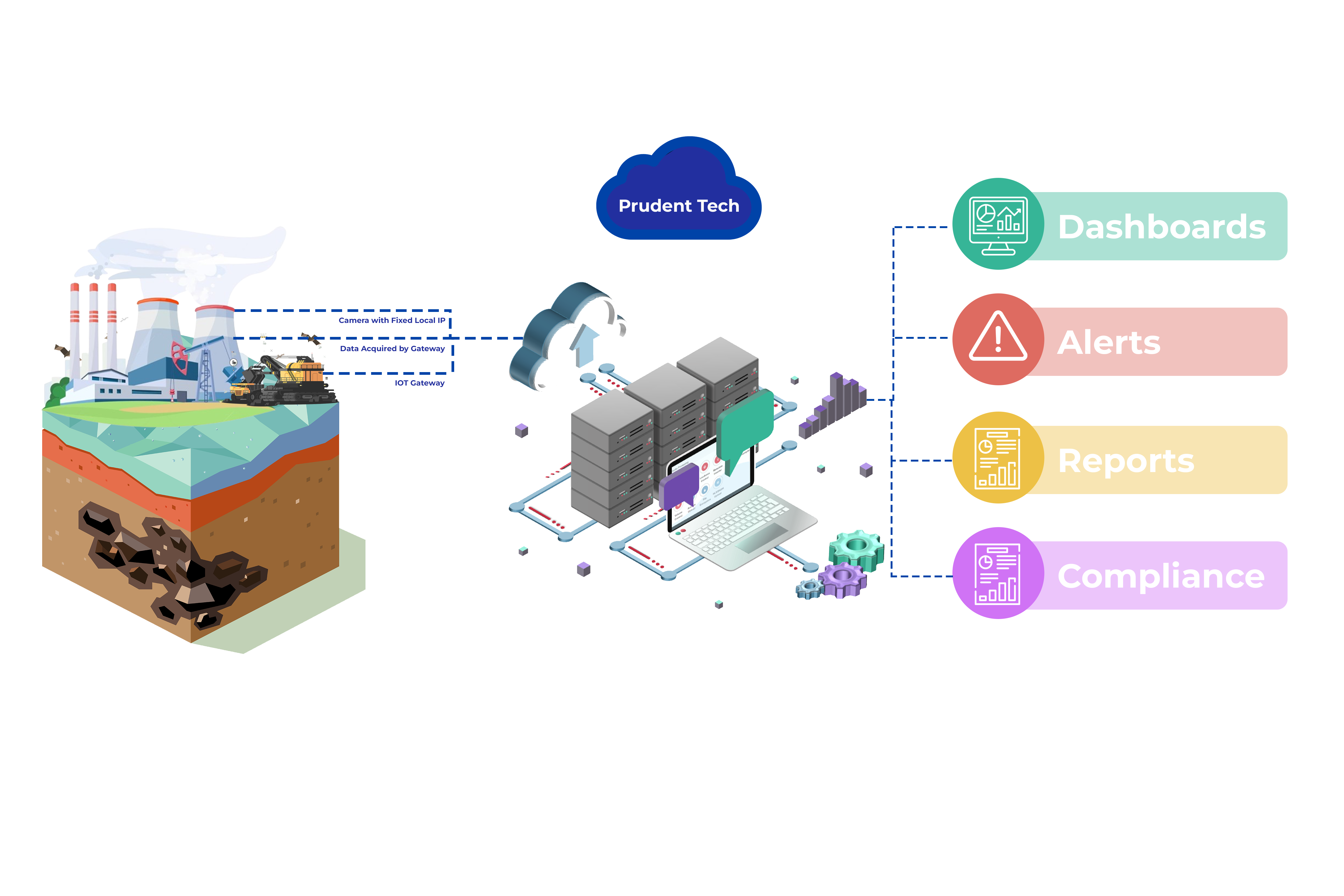

The Sustainability Cloud's componentsUnderstanding Continuous Emission Monitoring Systems (CEMS)

Regulatory authorities frequently require industries to install CEMS to monitor their emissions and ensure compliance with air quality standards and environmental regulations. These integrated systems (Analyser, Data logger, Vendor software, and Regulatory bodies Portals) are known as CEMS. CEMS gathers the Emissions data from the site and pushes that data to the regulator bodies using the internet and communication protocols.

Components of a CEMS

Gas analyzer

These are the primary parts that measure the amounts of particular pollutants in the exhaust gas stream. Different kinds of analyzers are used to find different kinds of pollutants, like particle matter (SPM), carbon monoxide (CO), sulfur dioxide (SO2), and nitrogen oxides (NOx).

Data logger

This data handling module ensures gathering and processing of the information obtained by the gas analyzers, it usually contains data logging and storage capabilities.

Communication interfaces

It offers a collection of guidelines, procedures, and standards that control the timing, format, and order of data exchange in order to guarantee smooth and effective communication between various hardware, software, and system components.

Data storage and reporting

Reporting of data to the CPCB and State pollution control boards as per their requirements.